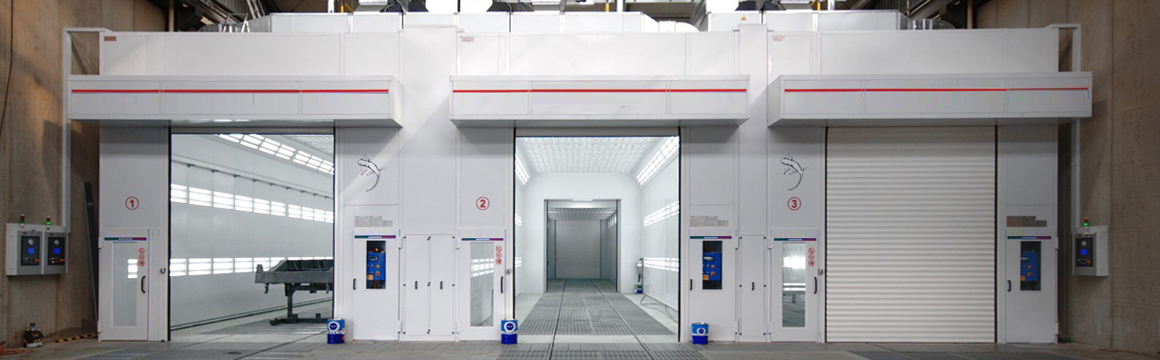

installation There are industrial installations which require special technical closures, like roller shutters able to withstand against hard and adverse environment and climatic conditions.

Oven booths, systems for drying, polymerization, curing, baking, cooling, sand blasing, handling and washing of steel, cooling towers or recycling installations, require roller shutters able to insulate both thermally and acoustically the rooms and able to withstand against humid or corrosive atmosphere.

I.S.E.A. has solutions which satisfy these conditions, roller shutters made by “noble” materials, like aluminium or stainless steel able to long-last in time and bad weather-resistant, and insulated roller shutters with high thermic/acoustic insulation.

During years, a great experience has been developed in special electrical operations, intensive uses, electronic control-boards suitable for each kind of industrial system to handle and to program control of roller shutters.

For high-risk explosion places (flame, spark, flammability of air, combustibles, gases,….) it’s possibile to have ATEX flame proof electric gear motors.

We designed and supplied closures suitable for use in special temperatures, using gear motors equipped with cooling fans or by special fittings with heating cables inside the vertical side guides.

All the solutions use strong, long-lasting and secure ignition systems, combined with safety and emergency systems.

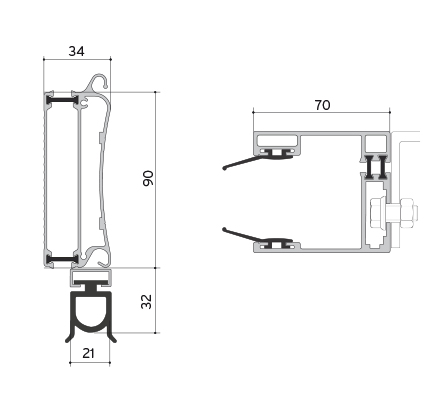

A COMPLETE THERMAL BREAK SYSTEM

- The entire system, curtain and vertical sliding guides, are thermal break.

- Polyamide bars are inserted into the profile and guides.

- The thermal bridge between the outside and the inside of the roller system is completely avoided.

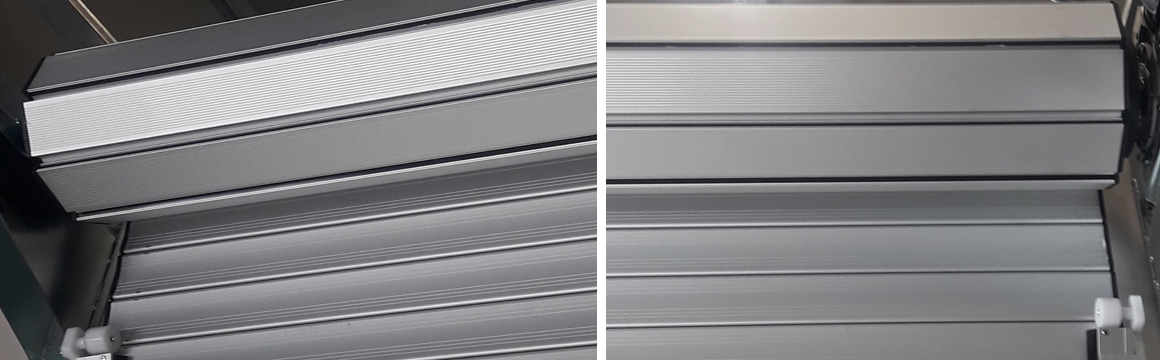

THE SLAT

The T.T. 90 slat, is obtained joining no. 2 extruded aluminum profiles.

The joining is made using a special mechanical process which includes the insertion of n° 2 polyamide bars to obtain the thermal break between the n° 2 insulation spaces.